|

ANPING YUANDONG METAL PRODUCT CO.,LTD

|

stainless steel wrie manufacturer

| Price: | 1003.0~4657.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We are the professional manufacturer of stainless steel wire. Stainless steel wire has wide usage. Stainless steel wire has a good ductility,etc.

1.

Quality: Could be produced as AISI, ASTM, BS, DIN, GB, JIS...etc.

2.

Quality: Could be produced as AISI, ASTM, BS, DIN, GB, JIS...etc.

2.

Type:

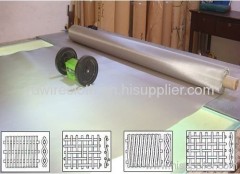

1). Stainless Weaving wire: Stainless steel has characteristics of corrosion resistance and heat resistance, after annealing in process, the wire finish is right and shinny. It is widely used in applications such as weaving and knitting wire cloth/mesh, braiding for flexible hoses etc.Package weight and/or length can be controlled in accordance with customers' requirement.

2). Stainless Spring wire: Available as bare, soap coated, resin coated as well as Cu-Ni coated wire, suitable for high speed automatic spring forming.

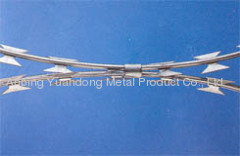

3). Stainless Rope wire: For producing wire rope and strand, due to its bright and clean finish, the wire rope and/or strand has a shinny and bright surface and well received for long-lasting and decorative construction industry applications.

4). Stainless Redraw wire: With physical properties, packing and finish to meet users' needs for best quality, production efficiency and economy.

5). Stainless Brush wire: In spools, coils or cut length, with tensile strength as required by the user.

6). Stainless Electro polishing Quality wire: For surgical utensils and other medical and sanitary applications as well as kitchen and bathroom products.

7). Stainless Pin wire: For surgical, fishing tackle, textile machinery and other applications requiring fine wire with accurate tensile strength and impeccable cleanliness

8). Stainless Straightened and cut bars: Produced on fully automatic machines which integrate drawing, straightening, grinding and cutting, guaranteeing consistency and accuracy.

9). Stainless Cut wire: Including shot wire and other wires made to customers' needs for chemistry, length, finish and accuracy.

2). Stainless Spring wire: Available as bare, soap coated, resin coated as well as Cu-Ni coated wire, suitable for high speed automatic spring forming.

3). Stainless Rope wire: For producing wire rope and strand, due to its bright and clean finish, the wire rope and/or strand has a shinny and bright surface and well received for long-lasting and decorative construction industry applications.

4). Stainless Redraw wire: With physical properties, packing and finish to meet users' needs for best quality, production efficiency and economy.

5). Stainless Brush wire: In spools, coils or cut length, with tensile strength as required by the user.

6). Stainless Electro polishing Quality wire: For surgical utensils and other medical and sanitary applications as well as kitchen and bathroom products.

7). Stainless Pin wire: For surgical, fishing tackle, textile machinery and other applications requiring fine wire with accurate tensile strength and impeccable cleanliness

8). Stainless Straightened and cut bars: Produced on fully automatic machines which integrate drawing, straightening, grinding and cutting, guaranteeing consistency and accuracy.

9). Stainless Cut wire: Including shot wire and other wires made to customers' needs for chemistry, length, finish and accuracy.

3.

Specifications of stainless steel wire:

Sizes of wire (diameter) : 0.1mm ~ 15.0mm

4.

Surface : Gray, Bright, Cleanliness, Coating.

4.

Surface : Gray, Bright, Cleanliness, Coating.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Steel Wrie

Stainless Steel

Steel Stainless

Cabinet Stainless Steel

Stainless Steel Bearing

Stainless Steel Wire Mesh

More>>